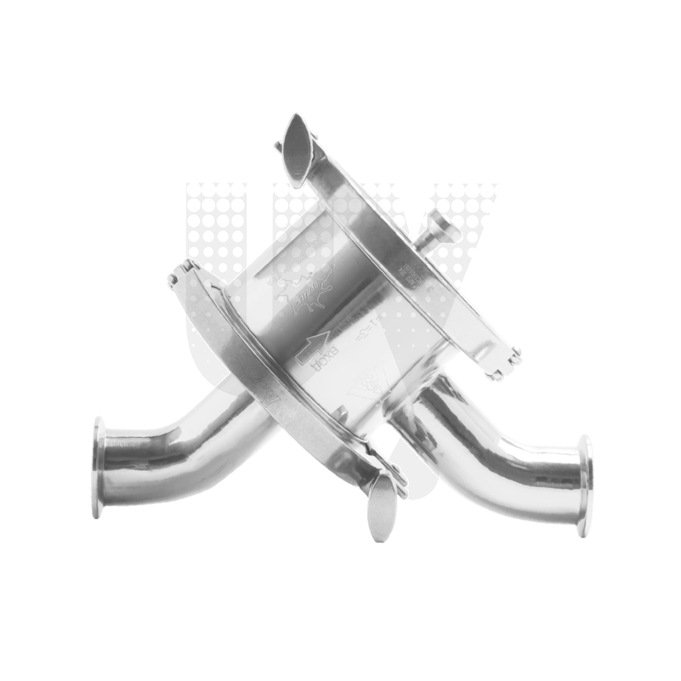

UVMILK® ULTRA Practic filter for ultra-fine purification of milk

Always get highest grade milk and get the reputation of a top-quality milk supplier with the finest filtering ever made.

In stock

- Remove somatic cells

Thanks to 3 μm filtration cells with our patented SomaticStop technology. - Top-grade milk

With the unique technology of PP thread winding clearing the milk from all impurities. - Double your profit from milk production

Start processing milk and sell it at a retail price with market premium. - Strengthen your company’s reputation

Always produce high quality milk with consistent test results. - Install it at any straight place in the dairy pipeline

The branch pipes are arranged conveniently. Each filter housing can be supplied with a set of individually selected fittings with different types of fastening. - Preserve fat content in milk

The unique winding of polypropylene thread lets elastic balls of fat easily pass through its polygonal cells.

How it works: The dirty milk is fed into the filter housing through the bottom pipe and under the pump’s pressure it flows through the cartridge from the center to the periphery. Finally, through the outlet in the side outlet pipe you get high quality milk with low somatic cell count.

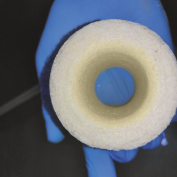

Filtering layers are arranged using a unique patented technology SomaticStop. Multilayer cylindrical channels of the filter element are formed by discrete layers of fibers, obtained by the aerodynamic extrusion of food grade polypropylene, smoothly merging into each other. The smooth transition between the layers reduces gaps in the flow and the hydraulic resistance of the filter element, increasing its throughput.

Microvilli of polypropylene are angled to the fibers in such a way that impurities and somatic cells get stuck in them and fat globules, having the ability to shrink and stretch, pass through the smallest channels of the filtering element without getting caught in it.

- The filter is most efficient during milking when installed prior to the cooling tank

- Install the filter in a straight section of the milk pipe near the cooling tank

- Cut the pipe (hose) where you are going to install the housing, and weld or fasten the connection kit with clamps

- Install the housing into the milking system by connecting the inlet and outlet connections to the appropriate fittings

- Milk enters the filter housing through the inlet in the bottom cap and passes under pressure through the filter element. Pure milk comes out through a branch pipe in the side of the housing

! The seals for the clamps must fit exactly into the slots on the housing cap and on the branch pipes, then the housing will be completely sealed

! The filter is installed after the pump

- Use UVMILK® ULTRA filter prior to the cooling tank right after milking while milk is warm to prevent dissolution of mastitis products and somatic accumulations.

- The seals for the clamps must fit exactly into the slots on the housing cap and on the branch pipes, then the housing will be completely sealed.

- To avoid hydraulic impact, after you install the filter first open the «ВХОД» (inlet), and then, when the housing fills up with milk, gradually open the «ВЫХОД» (outlet).

- After the declared amount of milk passes through the filter or after you finish milking, remove the replaceable cartridge and dispose of it together with other solid waste.

- One filter cartridge should be used for the declared amount of milk, and it’s total usage should not exceed 5 hours to prevent bacterial cell grow inside it.

- The system should be washed after each milking and a new cartridge should be installed on the next milking to prevent bacterial growth and milk going sour.

- The silicone seals in the housing should be replaced 2 times a year.

- To make UVMILK® ULTRA Practic filter work more efficiently an additional level of filtration is recommended prior to it. See UVMILK® Standard filter for more information.

Reviews

Suitable for your production

Топливный фильтр UVPETROL® для резервуара и котельной

Очистка от осадка после длительного хранения.

UVMilk LLC — we make filters

for food and petrochemical industry