Market analysis of whole milk products

The Russian dairy industry market is one of the largest and most significant sectors of the country's agro-industrial complex. Today, Russia ranks 4th in the world ranking of dairy producers.

We remain the country with the widest range of dairy products, occupying a significant part of our consumer budget. With a slight decrease in interest in milk and fermented milk products, the production of cheese and ice cream in the Russian Federation is increasing annually.

Milk consumption in Russia is 165 kilograms per capita. According to the Food Security Doctrine, the minimum threshold for milk self-sufficiency in the country should be 90%, but so far this figure is 84%.

Last year, imports of dairy products from non-CIS countries fell to almost zero, and from neighboring countries they decreased by 10%. Basically, the shortage of milk-containing products is covered by Belarusian neighbors.

When processing milk, various additives and ingredients are used to improve the taste and extend the shelf life. Filtration is designed to eliminate defects caused by random impurities and undissolved grains of dry ingredients.

When producing cheeses, butter, canned dairy products and baby food, additional requirements are placed on raw milk. The quality of the finished product is largely determined by the choice of proven and safe raw materials for production.

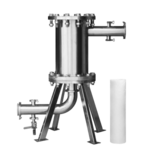

UVMILK filter range for dairy producers

for dairy production, 1 micron

for reconstitution of milk powder, 0.5 micron

for domestic needs, 5 microns

for purification of raw milk, 100 microns

from burns in pasteurized milk, 5 microns

from lumps in reconstituted milk, 5 microns

from mechanical dirt in prefabricated milk, 5 microns

for milk normalization, 4 microns

to improve emulsion texture, 4 microns

to increase shelf life, 4 microns

to improve the organoleptic characteristics of milk, 3 microns

for final cleaning of emulsion, 3 microns

for grading-up, 3 microns

to improve the indoor microclimate, M5 / 1 microns

for collecting milk powder during drying, F5 / 9 microns

to increase equipment life, G3 / 10 microns

for detergents, 5 microns

for disinfectants, 10 microns

for CIP washes, 1 micron

for production needs, 200 g/m3

for household needs, 80 g/m3

for domestic needs, 150 g/m3

Use of UVMILK filters in dairy production

Production of whole milk products and cheese

-

Bottled milk

-

Cheeses and cheese products

-

Dairy products

Problems in the production of whole milk products and cheese

- Mechanical impurities and somatics in raw milk, which increase the frequency of milk purifier unloading

- Colored foam and sediment in bottled milk, which leads to the return of products from retail chains

- A large number of somatic cells in milk, which leads to unstable heat resistance and reduced processability

- Unnecessarily unpleasant odor of raw milk due to poor milking hygiene on farms, which is transferred to the finished product

- Losses of raw milk and fat content during repeated unloading of sludge from milk purifiers, frequent equipment breakdowns

- Delamination and swelling of cheese heads due to high levels of coliform bacteria in raw milk

ADVANTAGES for whole milk and cheese producers

- Manufactured from virgin polypropylene and stainless steel, approved for use in the food industry

- Patented filter winding technology to improve the quality of milk by reducing bacteria and somatics

- Multilayer structure and combination of filter technologies, allowing to eliminate the smallest impurities and sediment ranging in size from 0.5 to 2000 microns

- The highest possible mechanical cleaning today, preserving dry matter, density and fat content

- Safety and inertness of filter materials during repeated contact with aggressive food and washing liquids

- Quick-release connections on the covers and pipes of the housings, allowing you to replace filter elements in a few minutes

Benefits for whole milk and cheese producers

- Bottled whole milk products without sediment due to the use of a control filter with a 3-micron fineness at bottling

- Pure whey and whey mixtures for sale due to the purification of semi-finished whey products from casein dust and milk fat

- Effective cleaning of brines and syrups thanks to a special technology of winding filter layers that retain threads, sand, grains of sugar and salt

- Stable production of cheeses and cheese products thanks to ultra-fine filtration, which improves heat stability and rennet coagulability of milk

- Protect against breakdowns and extend equipment life by preventing pressure surges caused by coarse dirt

- Economical consumption of enzymes and starter cultures due to milk filtration upon receipt and pasteurization, preventing fermentation defects

Economic justification

The plant receives 250 tons of raw milk daily. Centrifugal milk purifiers and pumps with an average cost of 2,500,000 rubles are being received. Repairing a milk purifier costs about 250,000 rubles. When receiving untreated milk, mechanical impurities enter the equipment components. With a purchase price of raw materials of 36 rubles per liter and a loss of milk during unloading with sludge of about 300 liters per day, the plant loses 324,000 rubles per month. Total losses during equipment repairs and unloading are about 574,000 rubles.

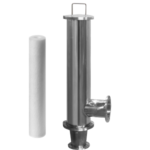

Use of the UVMILK Slot Filter at the receiving site XL and Milk Filter UVMILK Titan allows you to ensure stable operation of milk receiving equipment, thereby protecting production from forced downtime, as well as high-quality purification of raw milk for further processing. Filtration costs: By investing 320,000 rubles at a time on filtration, you will receive stable milk receiving equipment and savings on its repairs and milk losses of more than 570,000 rubles. Filter payback period: about two weeks.

Client case

Given:

At the milk receiving area, milk purifiers are installed, the sludge from which is unloaded every 15 minutes. With each unloading, 20 liters of milk are lost along with the sludge.

Task:

Reduce the load on milk purifiers, thereby protecting them from breakdowns, and the line from downtime, and also reduce the frequency of unloading and loss of milk at the primary receipt stage.

Solution:

Installation of a slot filter for preliminary purification of milk from large mechanical impurities up to 200 microns in size and a milk filter UVMILK Titan with a cleaning fineness of 5 microns.

Result:

Thanks to the cascade filtration installation, it was possible to protect milk clarifiers from breakdowns, increase unloading intervals to half an hour and reduce losses of raw milk.

Feedback on the use of UVMILK milk filters

«In the semi-hard cheese production workshop, we have been using filters from the UVMILK company for several years. We pass the mixture to make cheese through the UVMILK filter unit. The cleaning fineness of the installation is 10 microns. After use, dirt and carbon deposits are visible on the filter, which come out of the grease trap. We are very pleased with the filters.

At first we used 5 micron filters, but they clogged very quickly, so we increased the micron size. With ten-micron filters the results are excellent. We change filters once a day. In addition, we purchased water filters from UVMILK and installed them on 4 lines. We change every 10 days. The result is much better than with filters from another manufacturer.”

Volga processing plant, Chuvashia

Production of canned dairy products and ice cream

-

condensed milk

-

powdered milk

-

ice cream

PROBLEMS OF PRODUCTION OF CANNED DAIRY PRODUCTS AND ICE CREAM

- Mechanical impurities in milk and ingredients that give the raw material a gray tint and an unpleasant taste

- Burn marks, sugar crystals in milk and syrups, which leads to changes in the consistency, shade and aroma of the finished product

- Large particles of fillers, wafer crumbs and wood chips in illiquid ice cream, which makes it difficult to process

- Heterogeneity of the emulsion and syrups, which leads to the need for repeated homogenization of semi-finished products

- Metallic inclusions and taste in condensed milk, which reduces the likelihood of repeat sales when sold

- Lumps of undissolved milk powder disrupt the consistency of the reconstituted product and give it a characteristic taste

ADVANTAGES OF UVMILK FILTERS FOR THE PRODUCTION OF CANNED DAIRY PRODUCTS AND ICE CREAM

- Robust design of steel filter elements for homogenization and declumping of viscous dairy products

- Quick-release connections on the covers and pipes of the housings, allowing you to replace filter elements in the shortest possible time

- Long service life and backwashability of stainless steel filter equipment

- A wide range of filter life and micron size, allowing you to choose a cleaning solution for volumes from 100 liters to 500 tons of dairy products

- Mirror polishing of the inner surface of the filters allows for quick, complete flushing of the system

- The magnetic rod together with the steel filter eliminates the smallest metal chips and dust even on products with high viscosity

BENEFITS FOR CANNED DAIRY PRODUCTS AND ICE CREAM PRODUCERS

- Pasteurized milk without sticking thanks to the winding technology, which ensures fine cleaning of even the smallest particles after pasteurization

- Optimization of filtration costs thanks to low cost replacement cartridges capable of purifying milk and thickened emulsions

- Safety and heat resistance of the filter due to its manufacture from virgin polypropylene, which can withstand temperatures up to 130 degrees

- Uniform consistency of emulsions thanks to a filter that removes films, foam, lumps from pasteurized and reconstituted milk powder

- Reuse of an illiquid product by cleaning it from chocolate, wafer crumbs and filler particles

- Normalization of the mixture intended for drying due to the purification of the milk mixture from impurities that give an unpleasant odor and color

economic justification

The cold storage plant produces 20 tons of ice cream daily. Due to discrepancies in weight and shape parameters, up to 1 ton is rejected. With an average price of 600 rubles per kilogram of ice cream, the lost profit is 600,000 rubles per day. According to the technological process, it is permissible to use substandard products up to 5% of the volume of the produced batch of ice cream. In this case, the substandard must be cleaned of debris and sawdust of wooden sticks, chocolate and wafer crumbs, and remnants of fillers. At the same time, it is necessary to normalize the organoleptic characteristics of the rejected ice cream and emulsion.

Using the UVMILK filter for whole milk and emulsion allows you to remove all unwanted inclusions from substandard products, thereby preparing them for reuse. Additionally, the texture of the emulsion is evened out, making the product more uniform. By investing 70,000 rubles at a time on a set of housing and filter elements, you will be able to recycle substandard products and receive no losses due to rejection of more than 600,000 rubles daily. Filter payback period: one day.

client case

Given:

The condensed milk production line produces 15 tons of products per day with a dry matter content of less than 50%. After pasteurization, burnt marks, mechanical inclusions and coagulated protein are found in raw milk.

Task:

To establish constant cleaning of raw milk from foam, coagulated protein, and foreign mechanical impurities to ensure a pleasant creamy aroma and creamy tint of the finished product.

Solution:

Installation of the UVMILK slot filter with a cleaning fineness of 250 microns and the UVMILK filter for whole milk and condensed emulsion with a cleaning fineness of 10 microns.

Result:

Thanks to the sequential installation of filters with different micron sizes, it was possible to establish effective cleaning of the thickened mixture with a convenient interval for washing and replacing filter elements.

FEEDBACK ON THE USE OF UVMILK MILK FILTERS

“When producing condensed milk, we are faced with the task of ensuring stable organoleptic characteristics. After pasteurization, burnt marks formed in the raw materials, affecting the color and smell of the product. Also, the consistency of the finished product required additional homogenization and cleaning from undissolved particles. The previously installed filter was deformed under pressure.

It was decided to install a UVMILK filter for fine purification of milk after pasteurizer and a UVMILK slot filter for condensed milk, which retains lumps and undissolved sugar. As a result of filtration, milk leaves the pasteurizer without dark inclusions or burnt marks. The consistency of the finished product has improved, eliminating unwanted lumps and grains of caramelized syrup.”

Dairy plant, Belgorod region

Collection and transportation of milk

-

MILK COLLECTION

-

TRANSPORTATION OF MILK

-

PUMPING MILK

PROBLEMS when collecting raw milk

- High risk of souring of the entire volume of collected milk due to mixing of milk produced in violation of milking and storage hygiene

- Low profitability of business activities due to poor quality and price of raw milk

- Rapid bacterial contamination and increased indicators of somatic cells do not allow one to qualify for a higher grade

- Refusals to accept milk due to deviations in organoleptic properties and visible mechanical inclusions

- Lack of cleaning equipment upon receipt and long transportation of milk lead to the dissolution of dirt in the milk

- Income does not allow the purchase of a modern milk purifier, since all costs for collection, processing and transportation are borne by the collector himself

ADVANTAGES OF UVMILK FILTERS FOR prefabricated milk

- Compactness of filter equipment, allowing installation in small rooms and on milk tankers

- Specialized filtration equipment designed to meet mobility and quick installation requirements

- Unique winding technology that allows you to trap contaminants inside the body of the filter element, while allowing fat globules to pass through

- Improved service life of filter elements for effective cleaning of the entire batch of received milk

- A wide range of polypropylene and steel filters with a micron rating from 0.5 microns for somatic and mechanical milk purification

- Low energy consumption when filtering milk due to the minimal resistance of polypropylene and steel cartridges

BENEFITS FOR Raw Milk Collectors

- Increasing the shelf life of milk for subsequent transportation or processing by reducing bacterial contamination and acidity

- Preservation of original fat content thanks to unique winding technology, allowing fat globules to pass freely

- Increasing the purity group of collected milk by removing mechanical impurities from milk with a size of 4 microns

- Easy installation and compatibility with existing equipment due to filter design and compact size

- Continuous filtration process when pumping milk thanks to milk purification without stopping to change filters

- A visual indicator of the purity of the milk received due to the snow-white color of the primary polypropylene, on which all contaminants and mastitis products are visible

economic justification

After collecting 10 tons of milk per day from several farms, the collector pours the milk into a common tank. It happens that mastitis products, particles of feed, hay, bedding, wool and insects slip through, which significantly affects the cost of milk and its indicators: purity group, somatics, QMAFAnM, acidity, fat content. If the dairy plant detects dirty milk, acceptance will be refused or the milk will be accepted at a minimum price as substandard. In the worst case scenario, losses amount to 10 tons at 18 rubles/l or 180,000 rubles. in a day.

Using the UVMILK Medium filter will reduce the level of bacteria and somatics, while maintaining the original fat, protein and dry matter content. The quality and shelf life will increase. By investing 60,000 rubles. for a set of housing and filter elements, you will sell the entire volume of milk and receive an additional payment due to the improvement of its performance. Cost difference: 1.5 rubles per liter: 10 tons of milk * 1.5 rubles * 30 days = 450,000 rubles. Filter payback period: 4 days.

client case

Given:

The milk collection point collects about 12,000 liters of milk per day with a high percentage of mechanical impurities and somatics, which leads to increased bacterial contamination, reduced milk shelf life and grade jumps.

Task:

Clean milk from feed particles, litter, manure, hair and insects before pumping into the cooling tank to ensure the milk is suitable for delivery, processing during storage and transportation to the dairy plant.

Solution:

Installation of a UVMILK mesh filter with a cleaning fineness of 500 microns and a UVMILK Large filter with a cleaning fineness of 4 microns for consistent cleaning from large and small foreign matter.

Result:

Thanks to double purification of collected milk using filters with different micron sizes, mechanical impurities and somatic substances are eliminated, color and smell are improved, and the grade and shelf life of milk are increased.

REVIEW ON THE USE OF uvmilk MILK FILTERS

“We accept milk from several distributors; during pumping, dirt is not always visible, but when draining from the tank, there is sediment in the last liters. We use 10-ton filters from UVMILK to purify the milk we accept. At the inlet, the filters are white, clean, at the outlet all mechanical impurities and all sorts of nasty things remain on them. There are no complaints about the filters, they work great.

We tried filters from other manufacturers, but the quality of both the filters themselves and the milk after cleaning was noticeably worse. We have been working with the UVMILK company since 2017. Since our cooperation, there have been fewer complaints from dairy factories about milk contamination. We don’t want to risk the quality of milk; we work with a trusted supplier.”

Milk collection point, Ryazan region