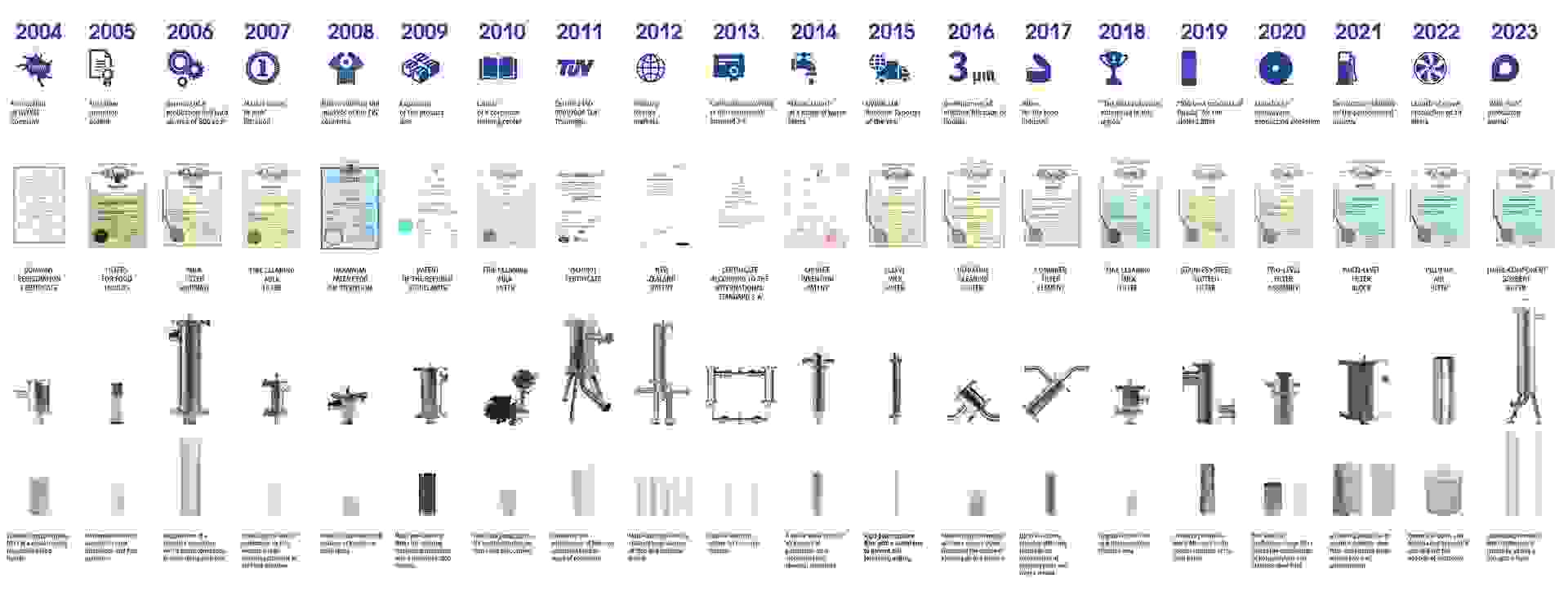

2004

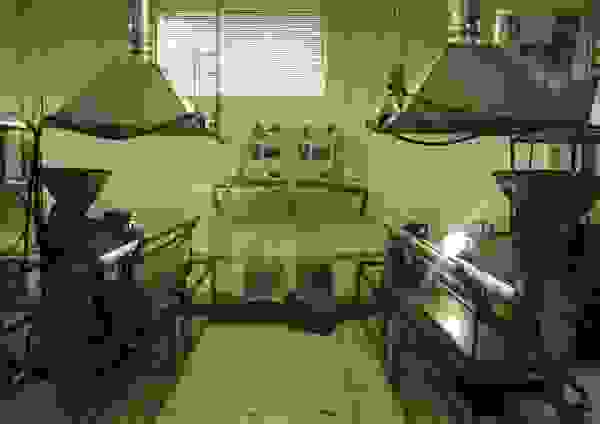

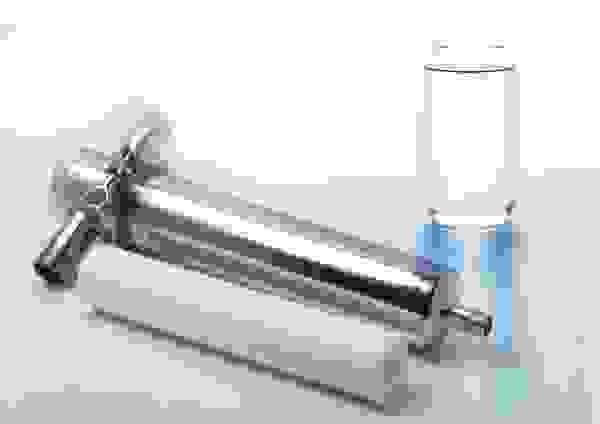

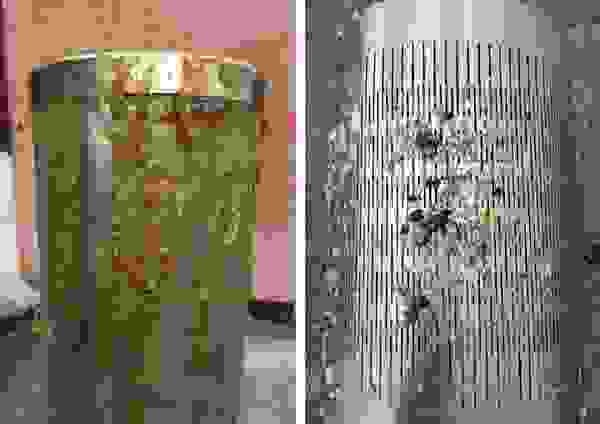

Especially for Russian agricultural enterprises that are faced with the problem of milk purification, the UVMILK company has developed an innovative milk filter. The main task of the company at that time was the development and testing of technology that would allow milk to be purified more efficiently.

The first UVMILK polypropylene filters were produced on machines that were self-assembled by the company's specialists. In the process of inventing filters, the equipment went through several stages of improvement in design and functionality.

In the same year, the company sent a package of documents for registration of a legal entity and received a certificate of inclusion in the Unified State Register of Legal Entities. UVMILK is still a reliable supplier for agricultural, food and industrial enterprises.