Cleaning in dairy production

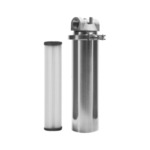

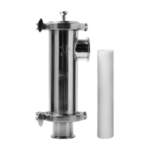

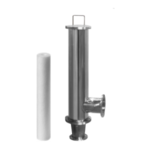

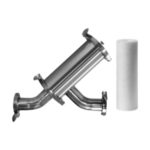

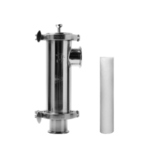

Ensure the purification of raw milk, brines, emulsions, syrups, whey, condensed milk and produce ready-made dairy products in the right volume and quality with a pleasant creamy color, taste and smell thanks to UVMILK filters that eliminate somatics, sediment, grains, burns and foreign inclusions.