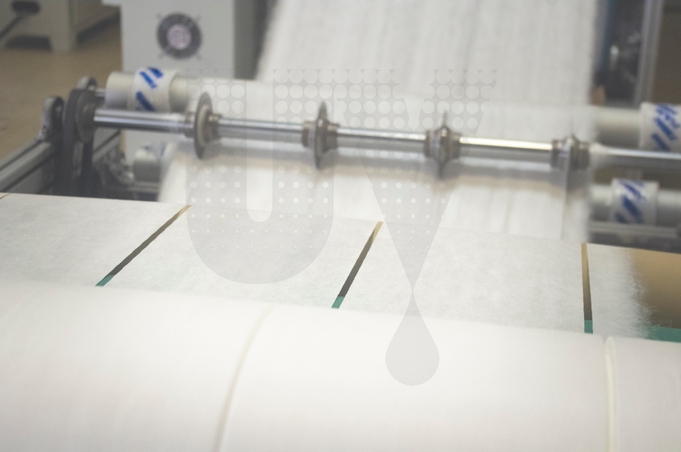

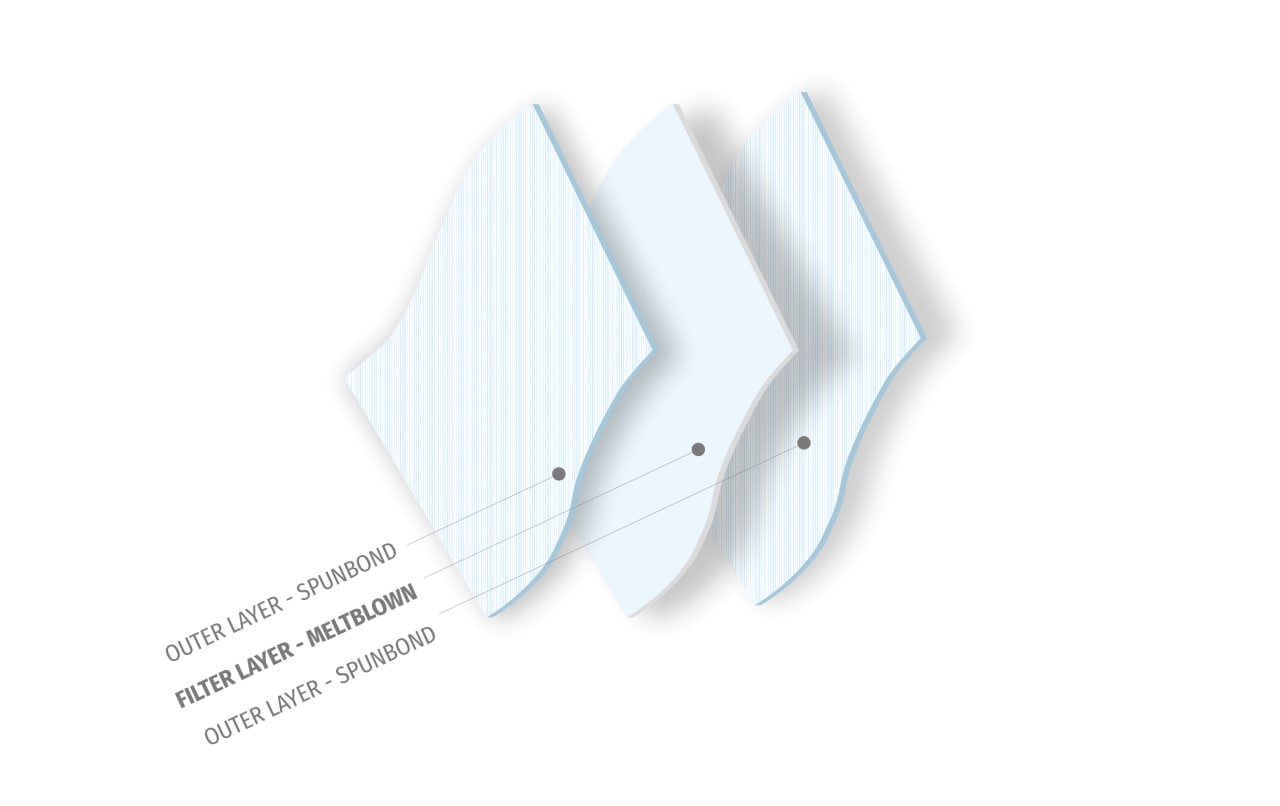

The manufacturing process for nonwoven fabric is significantly different from the manufacturing process for liquid filters. For our meltblown fabric we use only 100% certified raw materials from a European supplier, with no additives and no dyes.

Applications for Meltblown UVMILK® nonwoven fabric

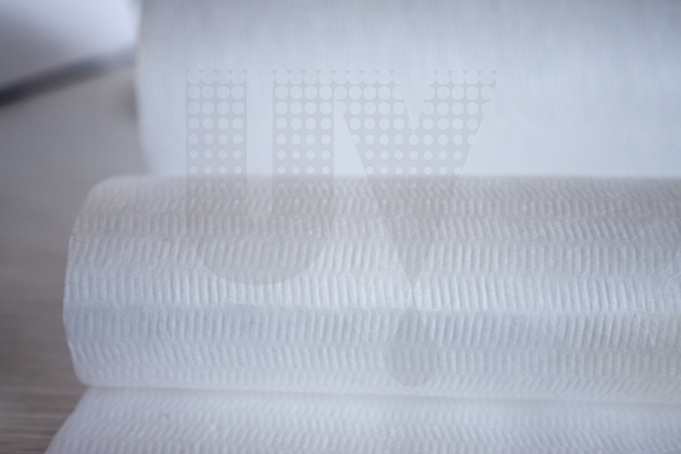

Melt blown nonvowen fabric has high protective properties, that make if a perfect material for disposable products like sanitary and medical face masks. The structure of this material prevents the penetration of liquids and bacteria. Our soft meltblown fabric has improved tactile properties and increased breathability.

Nonwoven fabrics with high filtration properties are also used to make respirators. Unlike masks, respirators are designed to provide a higher class of respiratory protection for people performing various types of industrial work, which are accompanied by the presence of construction dust, vapors, gases, and other particles in the air.

With it’s enhanced absorption properties and ability to withstand sterilization meltblown fabrics are used for sanitary and hygienic products (napkins and diapers), disposable bed linens, gowns, caps and other products used in cosmetology and healthcare. The lint-free surface of the material is soft to the touch and doesn’t irritate skin even after prolonged contact.

Here at UVMilk Company we can make nonwoven meltblown fabrics of various densities. Meltblown UVMILK® fabric with density of 80 g/m2 and higher is used as a filtering layer in various air filters. The range of applications is wide: from filters for household appliances to filters for industrial workshops.